The risk assessment (GBU) is a central instrument for ensuring occupational safety in the operation of wind turbines. Modern, object-oriented approaches enable a structured, digital recording of all hazards and measures per plant component – efficiently, legally compliant and easy to update. In this way, safety is systematically and sustainably integrated into everyday operations. In the following text, operators of wind farms will find further information on the implementation and the specific requirements of a GBU.

What is a risk assessment (GBU)?

The

Risk assessment (GBU) in the wind industry is a central element in the

occupational health and safety and serves the systematic identification, evaluation and

Reduction of hazards to which employees are exposed during their work

are. For operators of wind turbines, the GBU is required by law

and part of the security concept within the framework of the

Ordinance on Industrial Safety and Health (BetrSichV).

In contrast to the

purely technical examination of the stability of a wind turbine, the aim of the

GBU focuses on the safety of the people who work with the wind turbine in question – be it

during maintenance, repair or dismantling.

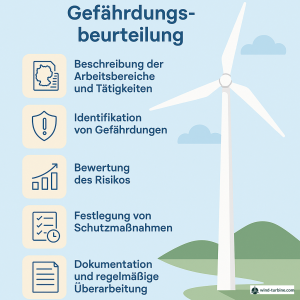

What are the typical contents of a risk assessment (GBU)?

A GBU must

can be created individually for each wind turbine or its components. They

based on the specific conditions on site, the

work equipment and the activities of the employees. Typical contents are:

- Description of the work areas and

Operations

- Identification of hazards, e.g. due to falls, electrical

Electricity, moving parts, confined spaces, weather conditions

- Assessment of the risk (frequency, severity of possible consequences)

- Determination of protective measures, e.g. personal protective equipment

(PPE), technical safeguards, organisational measures

- Derivation of inspection deadlines for safety-relevant facilities

(e.g. PPE, electrical systems)

- Emergency and rescue plans

- Documentation and regular

Revision, at least

annually or in the event of significant changes

According to BWE,

Test cycles for safety-relevant components such as fall arrest devices,

pressure vessels or fire extinguishing equipment and are part of the

Risk assessment.

What happens specifically in the event of damage to the wind farm?

Despite high

Safety standards can be used for almost 30,000 wind turbines in Germany

damage events cannot be completely ruled out. The root cause analysis

is then carried out by employers' liability insurance associations, experts or insurance companies.

Depending on the nature of the event – e.g. personal injury, fire or mechanical

Failure – will:

- Causes analyzed

- Components of comparable systems

checks

- Vulnerabilities documented

- Risk mitigation measures derived

These findings

flow into the further development of technical standards and into future

risk assessments. Operators are obliged to make use of such

events and to take appropriate preventive measures.

What is Object-Oriented Risk Assessment ?

An innovative approach

in the wind industry, the so-called object-oriented

Risk assessment. In this process, the classic GBU is digitized and converted into

an object-related, systematic structure . The basis of this

The procedure is to divide the wind turbine into individual

"Objects" such as:

- Tower

- Gondola

- Ascent systems

- electrical system

- Personal protective equipment

To each object

relevant hazards, protective measures, test specifications and responsibilities in

in a database.

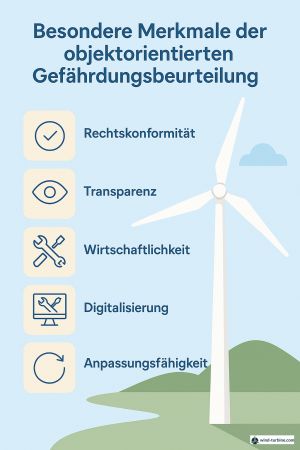

Advantages of object-oriented risk assessment:

- Compliance: The object-oriented GBU fulfils the

requirements of the Industrial Safety Ordinance and the

Occupational Health and Safety Act.

- Transparency: Hazards and protective measures are

Structured and traceable at any time.

- Economy: Synergies through standardized content

and easy copying to identical systems.

- Digitisation: Simplified maintenance, evaluation and

Disclosure of GBU data.

- Adaptability: The object-oriented structure

makes it easier to update technical or organizational

Changes.

A central aspect

the assignment of inspection and maintenance obligations is also directly

to the respective objects. This not only makes documentation easier,

but also improves safety through clear responsibilities.

Other providers also provide a similar form of

systematic, object-based risk assessment without having to

the focus is on the classic PDF report. Rather, the

information is dynamically maintained and continuously updated in order to ensure that the

short-term events or maintenance measures always up to date

.

Result

The

Risk assessment is an indispensable tool for ensuring

occupational safety in the operation of wind turbines. Modern concepts such as

the object-oriented GBU help to make this process more efficient,

more transparent and secure. They create the basis for a

predictive maintenance, clear responsibilities and a sustainable

Safety culture in the wind industry.